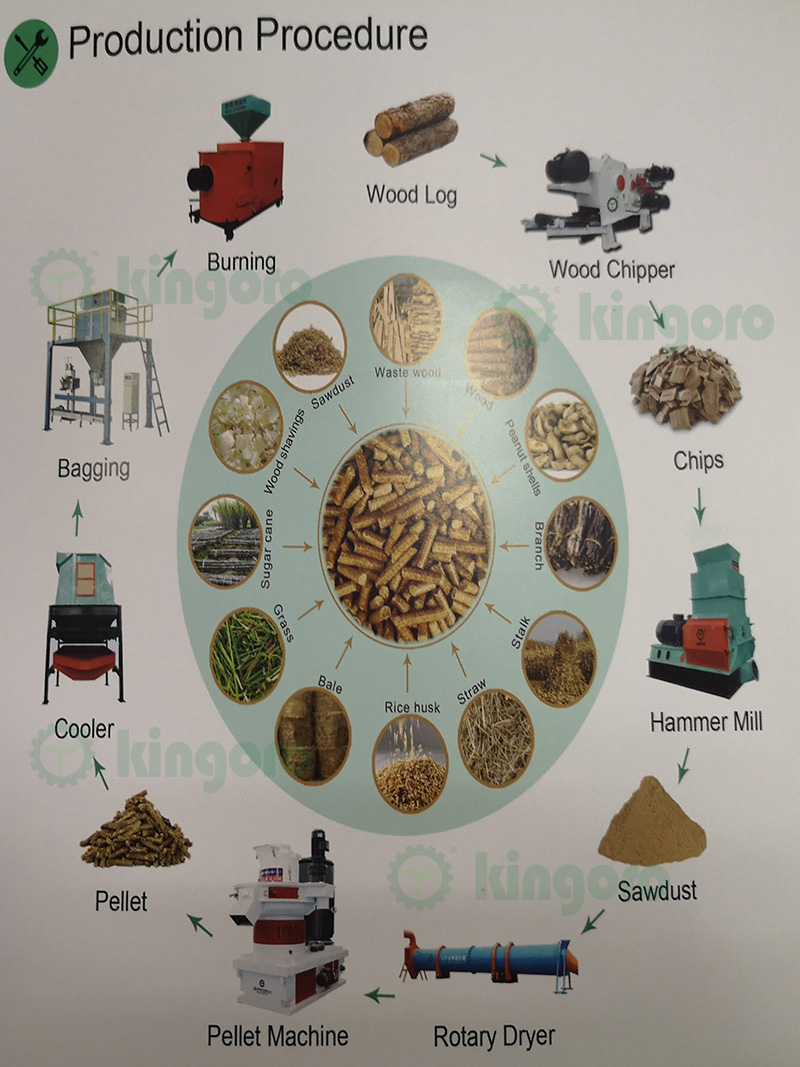

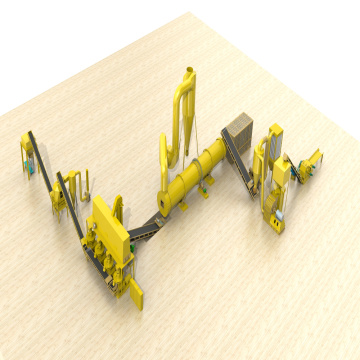

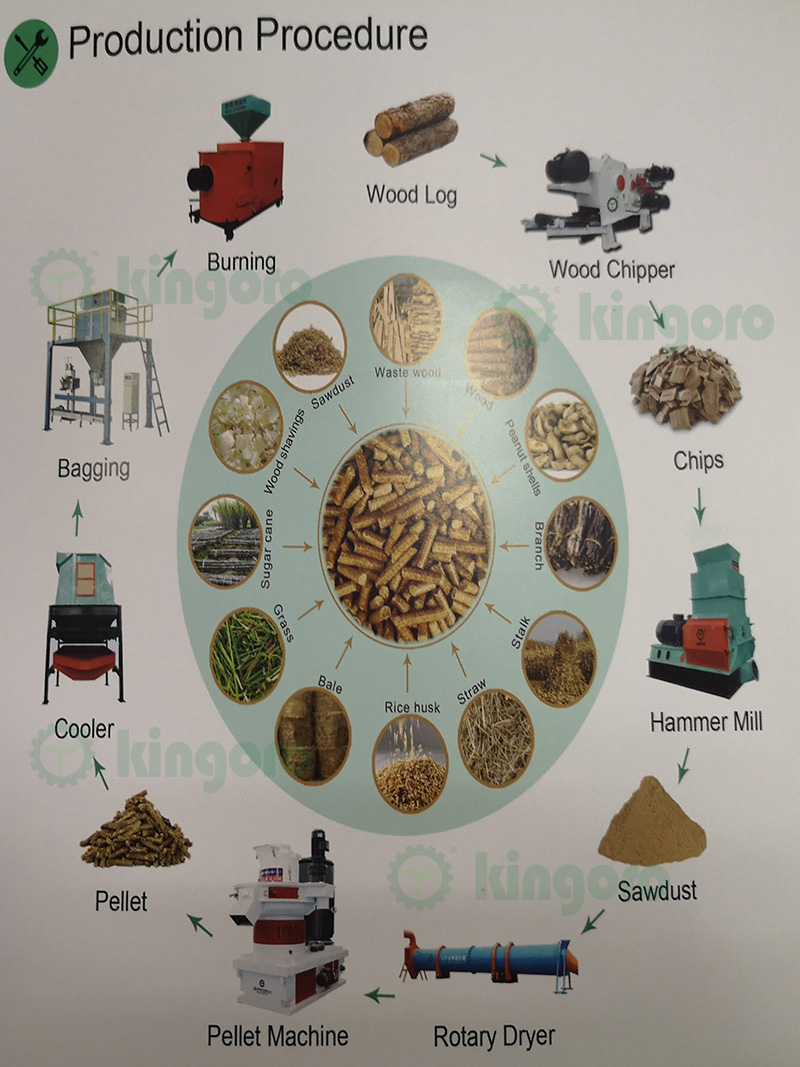

A Complete Biomass Pellet Production Line, from logs to biofuel pellets, includes main processes:

Chipping - Crusing - Drying - Pelletizing - Cooling - Packing.

Complete biomass pellet production line introduction

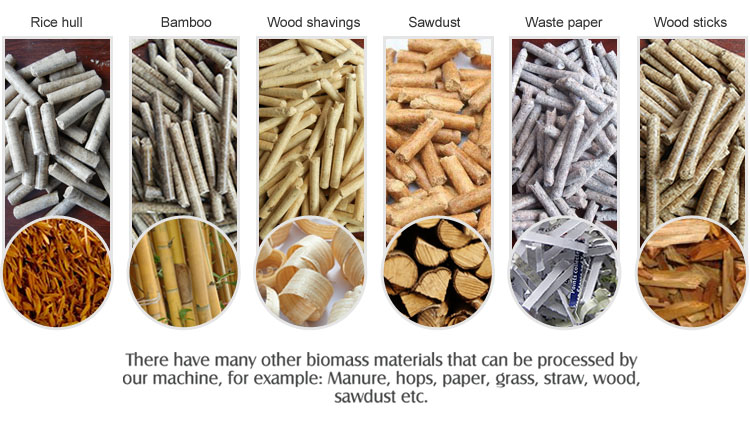

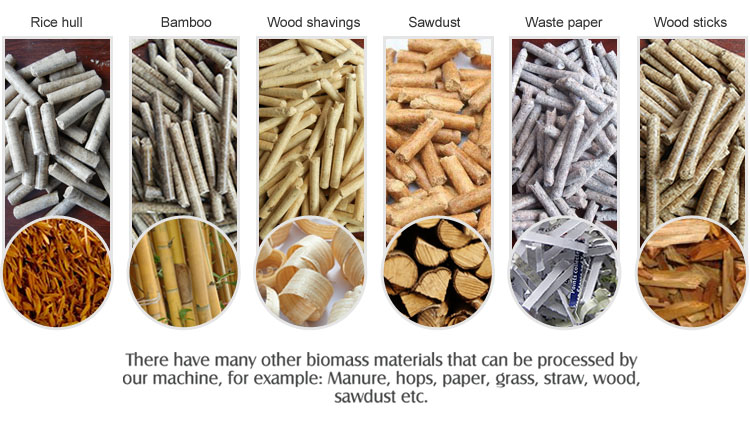

Pellet Samples from biomass pellet production line

1. Biomass wood pellet production line ------Chipping section, chipping wood log into wood chips (3-5cm).

2. Biomass wood pellet production line ----- Grinding section, gridning wood chips into sawdust/powder(1-5mm).

3. Biomass wood pellet production line --- Drying section, drying sawdust to moisture content 10-15%, for pelletizing, it requires materials moisture within 10-15%.

4. Biomass wood pellet production line --- Pelletizing section, pressing sawdust into biomass pellets(6-10mm).

5. Biomass wood pellet produciton line --- Cooling section, cooling biomass pellets to room temperature, after pelletizing, the pellets temperature at about 60℃, for storage, it need cooling.

6. Packing section for wood pellet production line, packing biomass pellets into bags for easy transportation and storage.Client will choose the weight of per bag pellets different according to requirement.

Our Company:

About Us

Shandong Kingoro Machinery Co.,Ltd, established in 1995, is specialized in manufacturing biomass fuel pellet making equipments, animal feed pellet making equipments and fertilizer pellet making equipments, including complete sets of a production line: crusher, mixer, dryer, shaper, siever, cooler, and packing machine.

According to specific requirements of our customers, we are enjoy to offer risk evaluation and turnkey solution plans. We focus on inventation and innovation. 17 patents are our achievement in scientfic research.

Our products are certificated with ISO9001, CE, SGS Test Report.

Our Main Products

A.

Biomass Pellet Mill 1.Vertical ring die pellet machine 2.Flat pellet machine

B.

Feed Pellet Mill C. Fertilizer Pellet Machine

D. Complete Biomass Pellet Production Line

Certificates of Biomass Pellet Produciton line