Flat Die Pellet Making Mill For Biomass

Get Latest Price| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Tianjin |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao,Shanghai,Tianjin |

Model No.: SZLH350

Brand: Kingoro

Voltage: 380V

Automatic Grade: Automatic

Energy Saving: Energy Saving

Certification: FDA

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Multi Color

Power: 30kw

Motor: Siemens Brand

Pellet Size: 6-10mm

Application: Make Biomass Pellets

Voltage And Frequency: 380V 50HZ, 3phase

| Selling Units | : | Set/Sets |

| Package Type | : | Export Package |

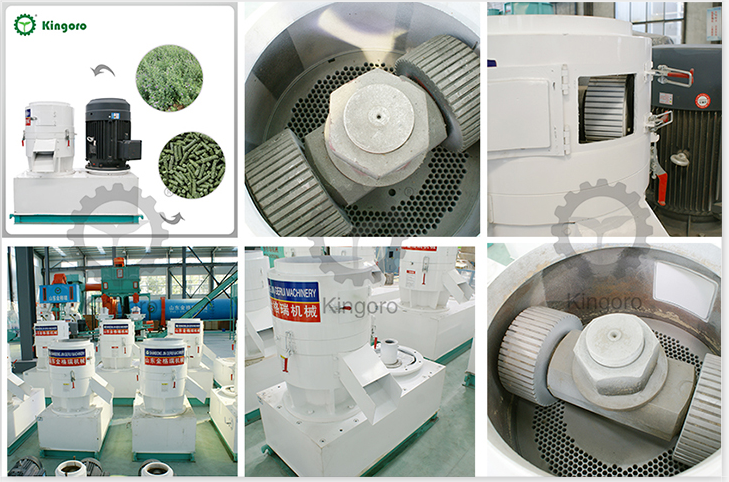

Flat Die Pellet Making Mill For Biomass Description:

Flat Die Pellet Mill For Biomass is for the customers who has a small capacity requirement, with short working time.

SZLH series is on the basis of absorbing advanced technologies domestically and abroad. It adopts mosaic rotating roller, during working process, the roller can adjusted as clients requirements.

Flat Die Pellet Mill Applicable Material:

Rice husk, sunflower seed shell, peanut shell and other melon shell; branches, trunks, bark and other wood scrap; all kinds of crop straw, rubber, cement, gray Slag and other chemical raw materials, etc.

Internal Structure

Flat Die Pellet Mill For Biomass Specification:

Model Power (kw) Capacity (kg/h) Weight (T) SZLH350 30 300-500 1.2 SZLH450 45 500-700 1.5 SZLH550 55 700-900 1.8

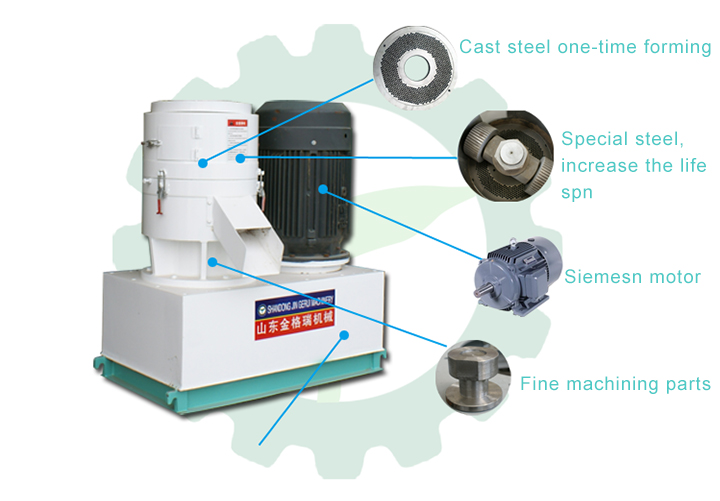

What are the advantages of our small pellet mill?

1. It adopts advanced Germanic advanced technology, with stable structure, the flat die and rollers is wear-resisting, heat-resistant.

2.It have best performance die and rollers, made from high quality wear resistant alloy steel with advanced quenching technology, increase output and extend service life.

3. The rollers are smoothly when working, its big body and unique design increase pressing place, increase production efficiency.

4.Finished pellet's diameter is 6, 8mm normally, can make according to customers` need .

5.It have got CE,ISO9001-2000 certification, all function have achieved European level

6.This mill with the advantage of closely structure, easily operation, stable performance

7.The pressed pellets with high density, high fuel value, low moisture, low ash content.

8.The gearbox is running by high precision gears. The gearbox and main shaft automatic recycling oil adding is realized by hydraulic oil inputting system.

FAQ

1.We need to know the following information to give a quote and solution

1)What is your raw materials? (to confirm mould pressure ratio of machines )

2) What is the moisture content of your raw material?

3)How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, becuase the suitable moisture content to enter pellet machine is 10-15%.

And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Will you send engineers to install the machines?

A: Of course. Our company has professional installation engineers team and specialized after-sale service team.

When the machines arrive your factory, we will send our installation engineers to your factory

Our engineers will Guide you to install the machines and training your workers how to operate the machines and maintain the machine.

4. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.