how to make alfalfa and rice husk pellets

Get Latest Price| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port,Shanghai Port,Others |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port,Shanghai Port,Others |

Brand: Kingoro

Voltage: 380V

Automatic Grade: Automatic

Energy Saving: Energy Saving

Certification: CE ISO SGS

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Multi Color

Motor: Siemens Brand

Pellet Size: 6-10mm

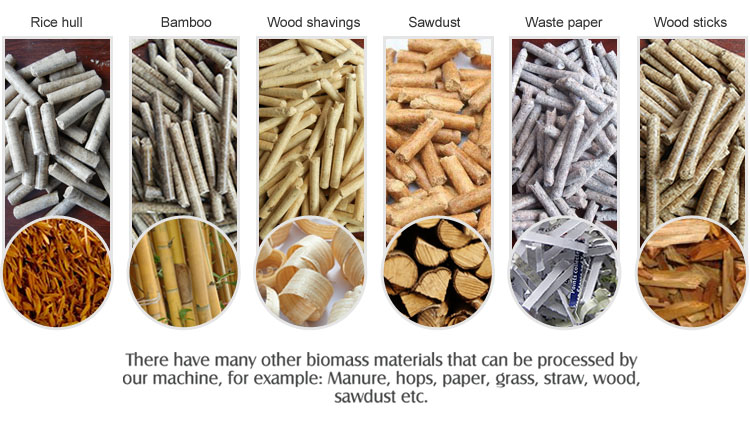

Application: Make Biomass Pellets

RAW MATERIAL: Sawdust, Rice Husk, Straw Etc

Voltage And Frequency: 380V 50HZ, 3phase

| Selling Units | : | Set/Sets |

| Package Type | : | Export Package |

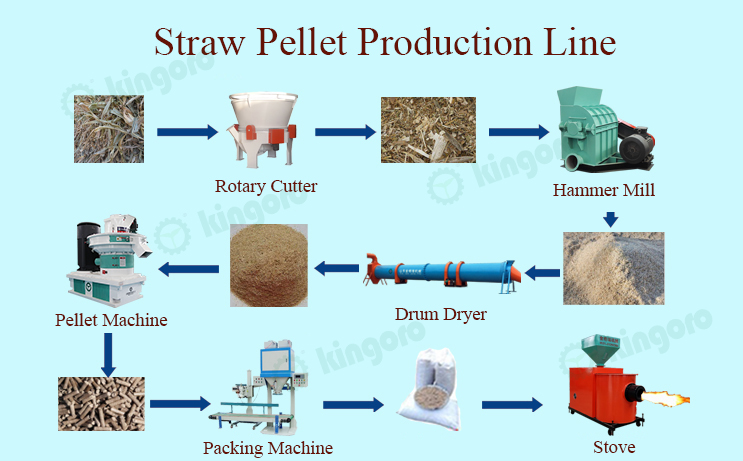

Wood Pellet Production Line and Straw Pellet Production Line introduction:

Pellets are a solid biomass fuel, mainly produced from wood residues but also from agricultural by-products such as straw. They have a cylindrical form with a diameter of 6 – 12 mm. Applicable for:residential heating, power generation, and for heat generation in the manufacturing and energy sectors.

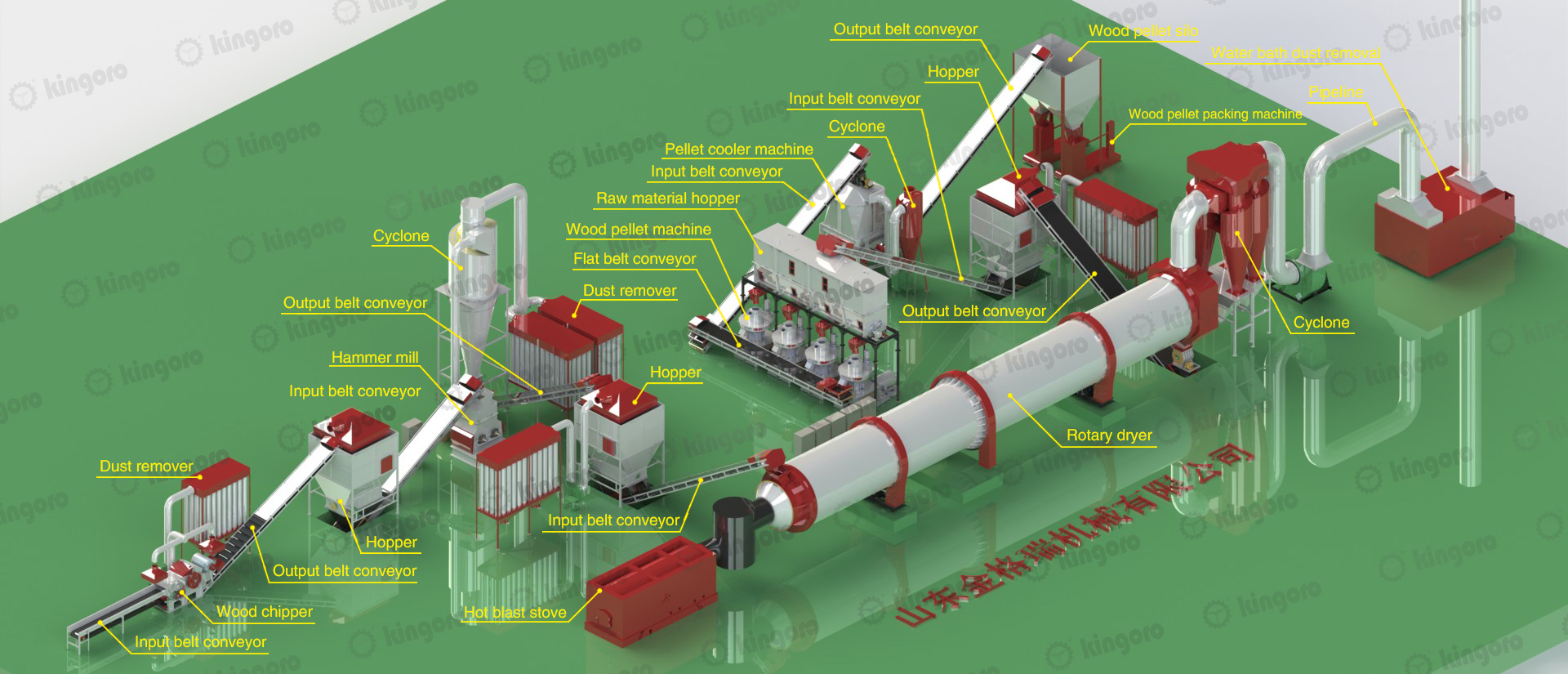

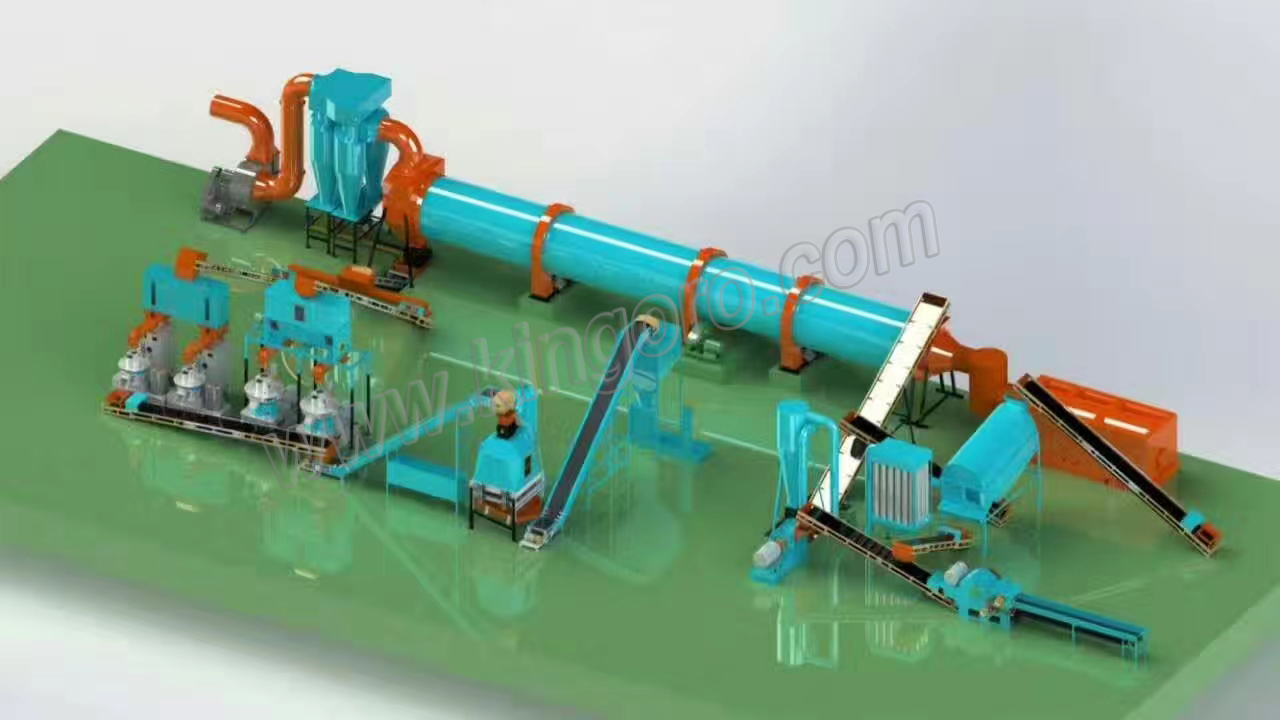

Complete Biomass wood pellets production line introduction:

Detailed introduction of each section, including: Wood Chipper, hammer mill, drum dryer, pellet machine, cooler, bagging machine

1. Biomass wood pellet production line------Chipping section, chipping wood log into wood chips (3-5cm).

2. Biomass wood pellet production line----- Grinding section, gridning wood chips into sawdust/powder(1-5mm).

3. Biomass Pellet Production Line --- Drying section, drying sawdust to moisture content 10-15%, for pelletizing, it requires materials moisture within 10-15%.

4. Biomass pellet production line --- Pelletizing section, pressing sawdust into biomass pellets(6-10mm).

5. Biomass pellet produciton line --- Cooling section, cooling biomass pellets to room temperature, after pelletizing, the pellets temperature at about 60℃, for storage, it need cooling.

6. Packing section, packing biomass pellets into bags for easy transportation and storage.Client will choose the weight of per bag pellets different according to requirement.

Our Company:

Shandong Kingoro Machinery was established in 1995 and has 23 years of manufacturing experience. Our company is located in beautiful Jinan, Shandong, China.

We are located in Jinan city, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our worker: We have over 300 employees, an annual sales figure that exceeds USD 40,000,000 and are currently exporting 80% of our production worldwide. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Certificate: We own 17 patents, among which there are 3 patents for invention. We have ISO9001 Certificate, CE Certificate, SGS Test Reports etc.

Our customers:

our product has been sold to different countries including UK, Serbia, Indonesia, Malaysia, Vietnam, Bangladesh ,Ghana, Suriname etc.

After service:

24 Hours Online Service.

Free training for operation, debugging and daily maintenance.

We can provide professional guide installation.

One year warranty and all-round after-sales service.

1.We need to know the following information to give a quote and solution

1)What is your raw materials? (to confirm mould pressure ratio of machines )

2) What is the moisture content of your raw material?

3)How many output capacity do you want per hour / month/ year?

Note: If the moisture is high, you need a dryer, because the suitable moisture content to enter pellet machine is 10-15%.

And please provide us above detailed information, then we would design the most suitable production line with reasonble offers.

2. Q: How long is your guarantee?

A: 12 months warranty but except quick wearing parts.

3. Q: Voltage requirement ?

A: Our machines can use 380V, 220V, 240V, 415V, 480V, and 50Hz, 60Hz.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.