Wasted Wood Pallet Pellet Production Line

Get Latest Price| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port,Shanghai Port,Others |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land |

| Port: | Qingdao Port,Shanghai Port,Others |

Model No.: SZLH560

Brand: Kingoro

Voltage: 380V

Automatic Grade: Automatic

Energy Saving: Energy Saving

Certification: CE ISO SGS

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Multi Color

Pellet Size: 6-10mm

Application: Make Biomass Pellets

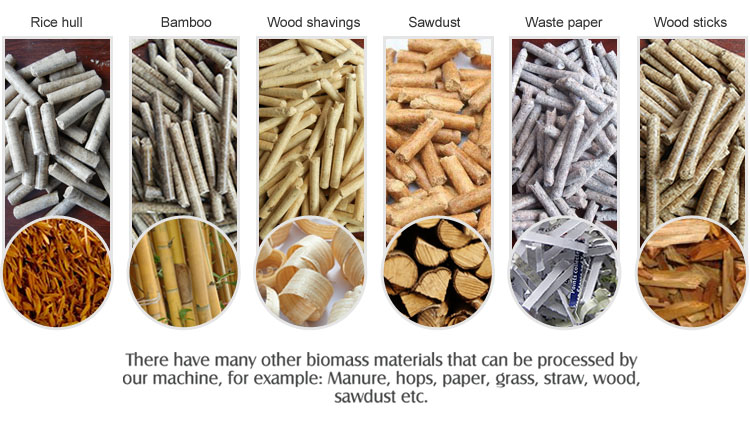

RAW MATERIAL: Sawdust, Rice Husk, Straw Etc

Voltage And Frequency: 380V 50HZ, 3phase

Transmission: Reducer Or Big Gear

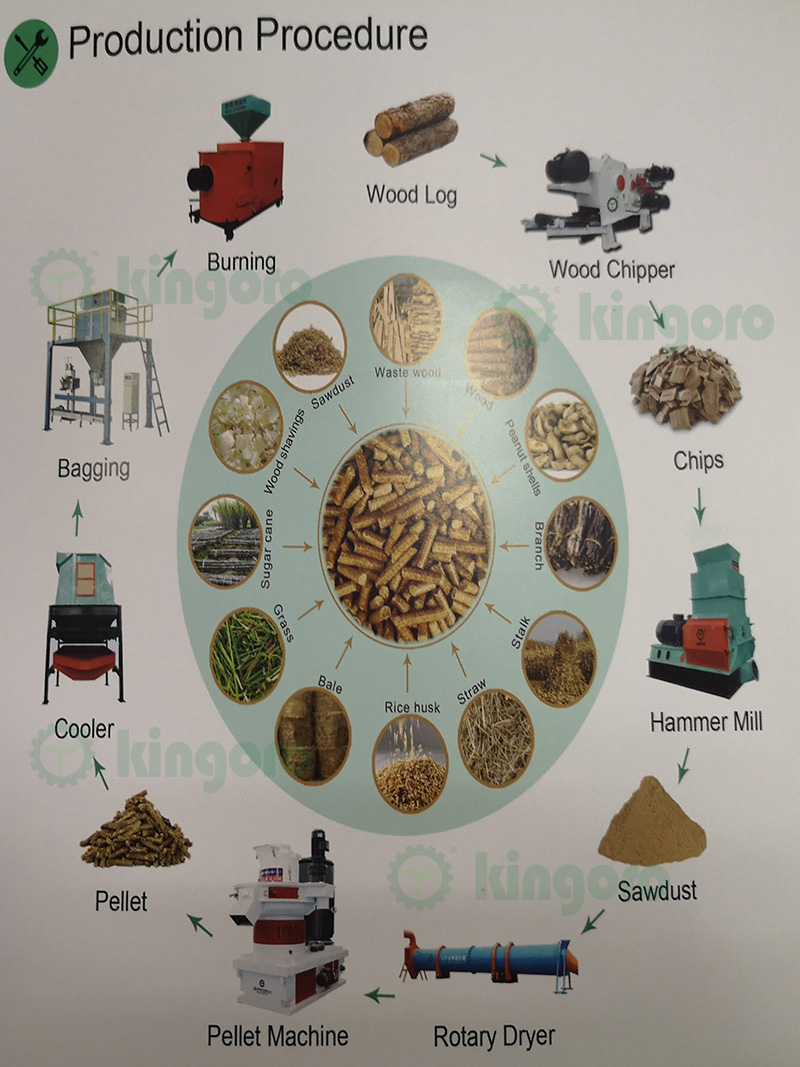

Processes: From Crushing Process To Bagging Process

Motor: Domestic Top 3 Brand Or Required Simens

| Selling Units | : | Set/Sets |

| Package Type | : | Export Package |

1t/h - 20t/h Biomass Wood Pellet Production Line

From Raw material(wood waste: wood pallet, wood chip, wood slab, log, branch, timber, lumber, wood offcut; agriculture waste: straw, stalk, husk ,shell, .....)

to biomass fuel pellets processing

Pellet samples from Biomass Wood Pellet Production Line

Complete Biomass Pellet Production Line introduction

1. Biomass pellet production line------Chipping section, chipping wood log into wood chips (3-5cm).

2. Biomass pellet production line----- Grinding section, gridning wood chips into sawdust/powder(1-5mm).

3. Biomass pellet production line --- Drying section, drying sawdust to moisture content 10-15%, for pelletizing, it requires materials moisture within 10-15%.

4. Biomass pellet production line --- Pelletizing section, pressing sawdust into biomass pellets(6-10mm).

5. Biomass pellet produciton line --- Cooling section, cooling biomass pellets to room temperature, after pelletizing, the pellets temperature at about 60℃, for storage, it need cooling.

6. Biomadd pellet produciton line --- Packing section, packing biomass pellets into bags for easy transportation and storage.Client will choose the weight of per bag pellets different according to requirement.

Our Company:

Shandong Kingoro Machinery was established in 1995 and has 23 years of manufacturing experience. Our company is located in beautiful Jinan, Shandong, China.

We are located in Jinan city, with convenient transportation access. All of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.