Europe Standard Wood Sawdust Pellet Mill Production Line

Get Latest Price| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao Port |

| Payment Type: | L/C,T/T,D/P,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FCA,CPT,CIP |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air |

| Port: | Qingdao Port |

Model No.: SZLH600

Brand: Kingoro

Voltage: 380V

Automatic Grade: Automatic

Controlling Mode: CNC

Energy Saving: Energy Saving

Certification: FDA

Warranty: 1 Year

Customized: Customized

Condition: New

Color: Multi Color

Name: Pellet Machine

Motor: Siemens Brand

Pellet Size: 6-10mm

Application: Make Biomass Pellets

Power: 380V/50HZ, 3Phase

Production: Biomass Pellet

| Selling Units | : | Set/Sets |

| Package Type | : | Export Package |

Product Description of Europe Standard Wood Sawdust Pellet Mill Production Line :

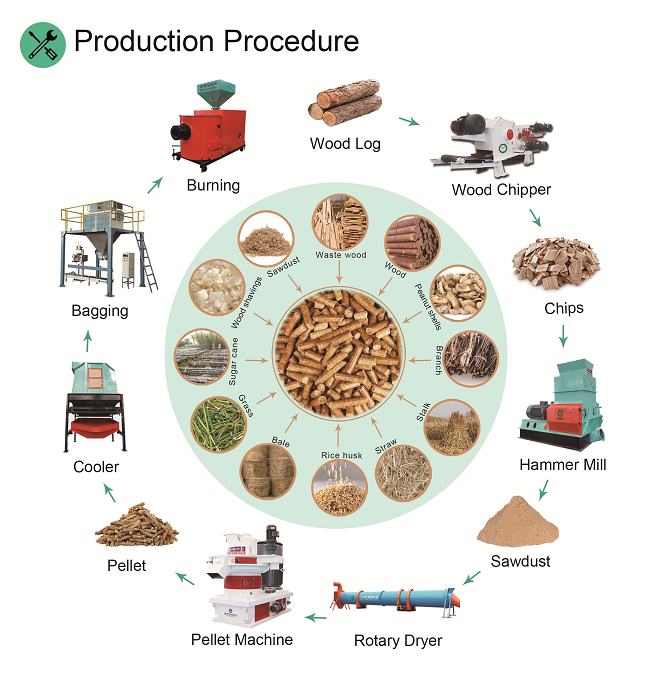

Europe Standard Wood Sawdust Pellet Mill Production Line is euipment for making the wood log/wood chips/sawdust/wood shaving/rice husk/stalk/grass...raw material into fuel pellets, Main process:

Wood Chipper--hammer mill--biomass dryer--Biomass Pellet Machine--pellet cooler--Pellet Packing Machine

wood pellet mill can suppress widely biomass raw materials such as wood shavings, branch,straw, rice husk,stalk,rubber ,bagass ,etc. with high effenciency and low cost.

The Pellet Machine with vertical ring die pellet machine absorbed the essence of pellet mill in oversea market,after our engineers improved,it had reached the international advanced level.

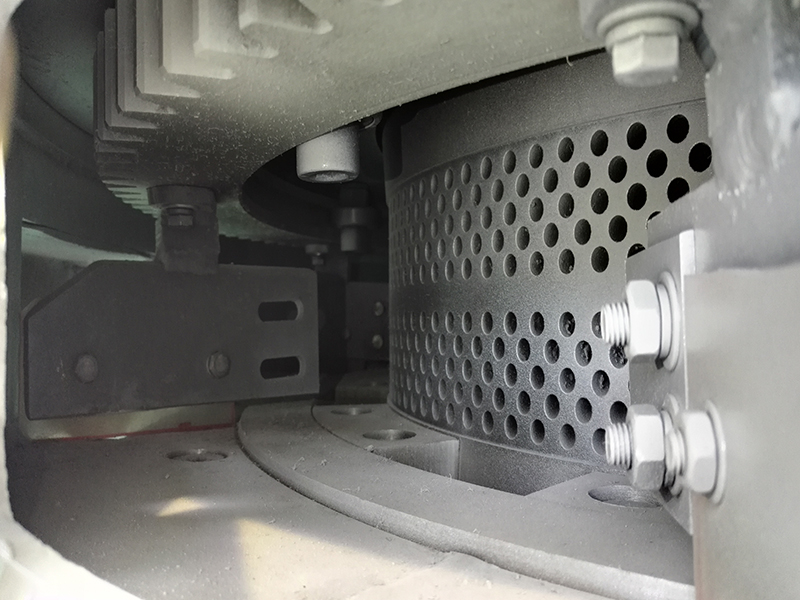

The heart parts of the Biomass Pellet Wood Sawdust Pellet Machine is [double Ring die" ,the double ring die has unique structural assembly and [rollers" are made of high quality wear resistant alloy steel.These two parts have the following characters: particular design, reasonable structure, low energy, high efficiency, long service life and so on.

Applicable Material for Europe Standard Wood Sawdust Pellet Mill Production Line :

Applicable to: rice husk, sunflower seed shell, peanut shell and other melon shell; branches, trunks, bark and other wood scrap; all kinds of crop straw, rubber, cement, gray Slag and other chemical raw materials, etc.

Pellet Production line

Specification of Biomass Pellet Mill:

Model SZLH470L SZLH560 SZLH560G SZLH580 SZLH600 SZLH660 SZLH760 SZLH850

Power (kw) Capacity (t/h) Weight (T) 55 0.7-1 2.6 90 1.2-1.5 5.6 132 1.8-2 6.5 90 1-1.5 5.5 110 1.3-1.8 8.6 132 1.5-2.0 8.8 160 1.5-2.5 9.6 220 2.5-3.5 13

Biomass Pellet Machine Details:

I : Transmission system

1. It adopts the hardened tooth surface to reduce the tooth surface, the tooth surface is widened, the modulus is increased, the meshing degree is large, and the load bearing capacity is enhanced, which is 3-5 times of the life of the conventional reducer.

2. The gear of the gearbox adopts the grinding process of the German NILES gear grinding machine. The transmission is stable, low noise , the service life is long, and it can withstand high power and heavy load.

3. The spindle is shortened and the torque is large.

4.The double ring die design to improve the efficiency of the pellet machine .

The ring die is still ,only the roller running whicg can reduce the pressure of Bearing ,cut down the cost of Pellet Machine,extend the service life.

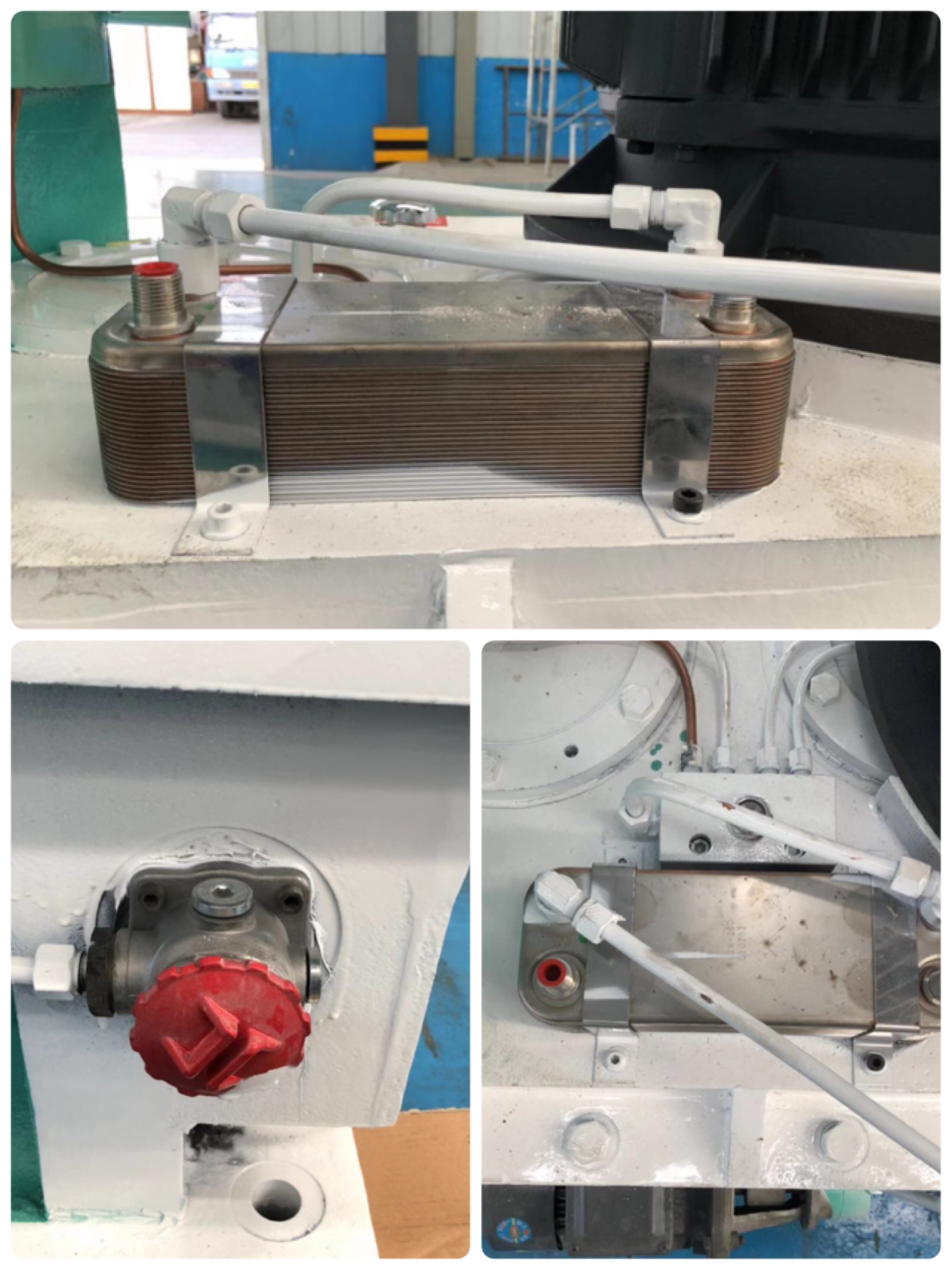

II: Lubrication system

1.The lubricating oil of the gearbox adopts independent water cooling system, can lower oil temperature, and increase the service life of internal bearings.

2, the spindle bearing uses the reducer's own thin oil lubrication, not only can reach the lubrication effect but also can lower the spindle bearing temperature.

3, the roller bearing adopts independent automatic oil filling system, regularly injection, good stability and long service life.

Our Company:

Shandong Kingoro Machinery was established in 1995 and has 23 years of manufacturing experience. Our company is located in beautiful Jinan, Shandong, China.

We can supply complete pellet machine production line for biomass material, include chipping, milling, drying, pelletizing, cooling and packing, according to different requirements of our customers. We also offer industry risk evaluation and supply suitable solution according to different workshop.

Kingoro as an advanced manufacturer of biomass pelletizers, owns 17 national patents and has obtained IS09001 quality system certification, CE certification, and SGS certification.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.