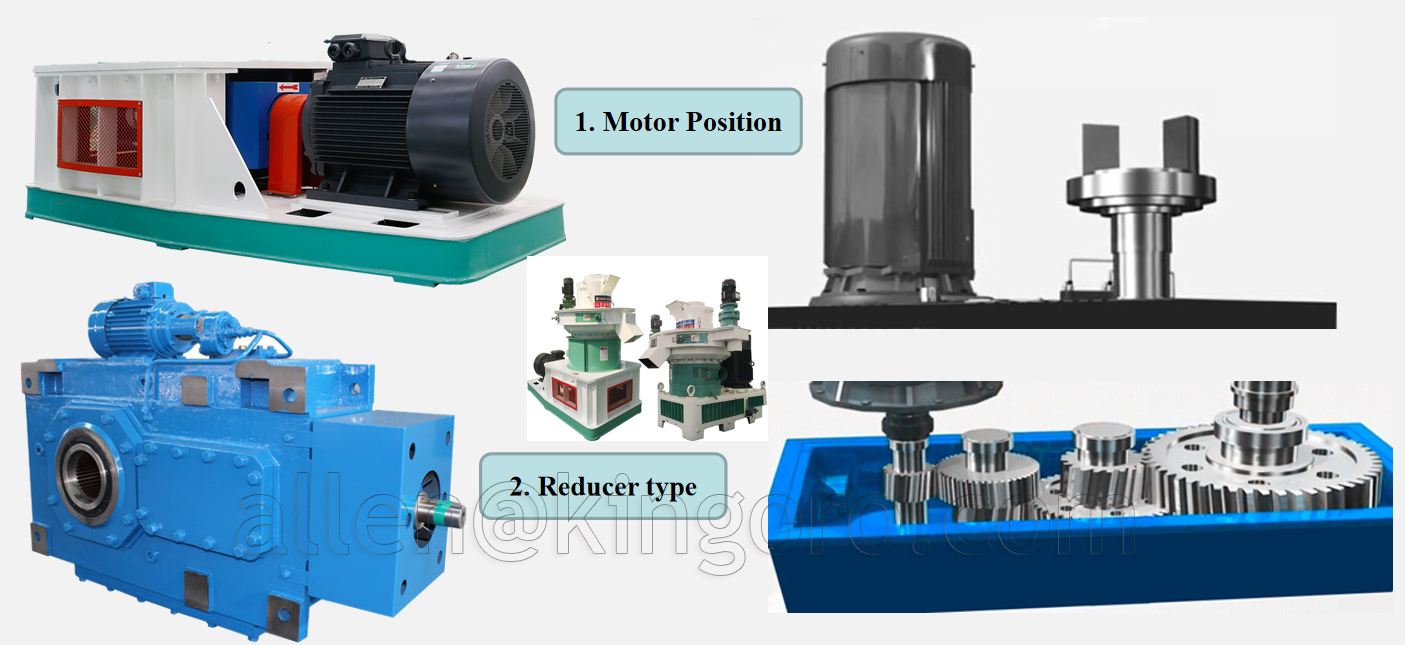

This Wood Pellet Mill is designed with big gear reducer, three level transmission, stable performance, low noice, long life time, energy saving.

This is the newest type of wood pellet mill in China market.

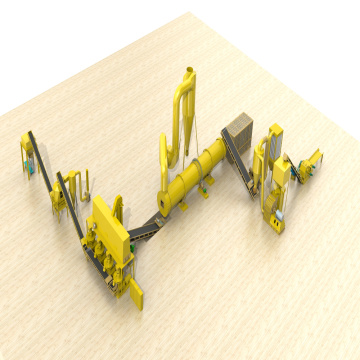

A set of wood pellet mill including feed screw conveyor, wood pellet mill, grease pump, duxt removal and connecting tubes

Specification of Kingoro Pellet Machine Biomass Wood Pellet Mill

| Model | Power kw | Capacity t/h | Size mm | Weight ton |

| SZLH580 | 90 | 1.2-1.5 | 2400x1300x2100 | 5.5 |

| SZLH600 | 110 | 1.3-1.8 | 2400x1300x2100 | 8.6 |

| SZLH660 | 132 | 1.5-2 | 2500x1300x1900 | 8.8 |

| SZLH700 | 160 | 1.8-2.5 | 2550x1600x2000 | 7.6

|

| SZLH860 | 220 | 2.5-3.5 | 2800x2000x2300 | 13 |

Advantages of Our Vertical Ring Die biomass Wood Pellet Mill

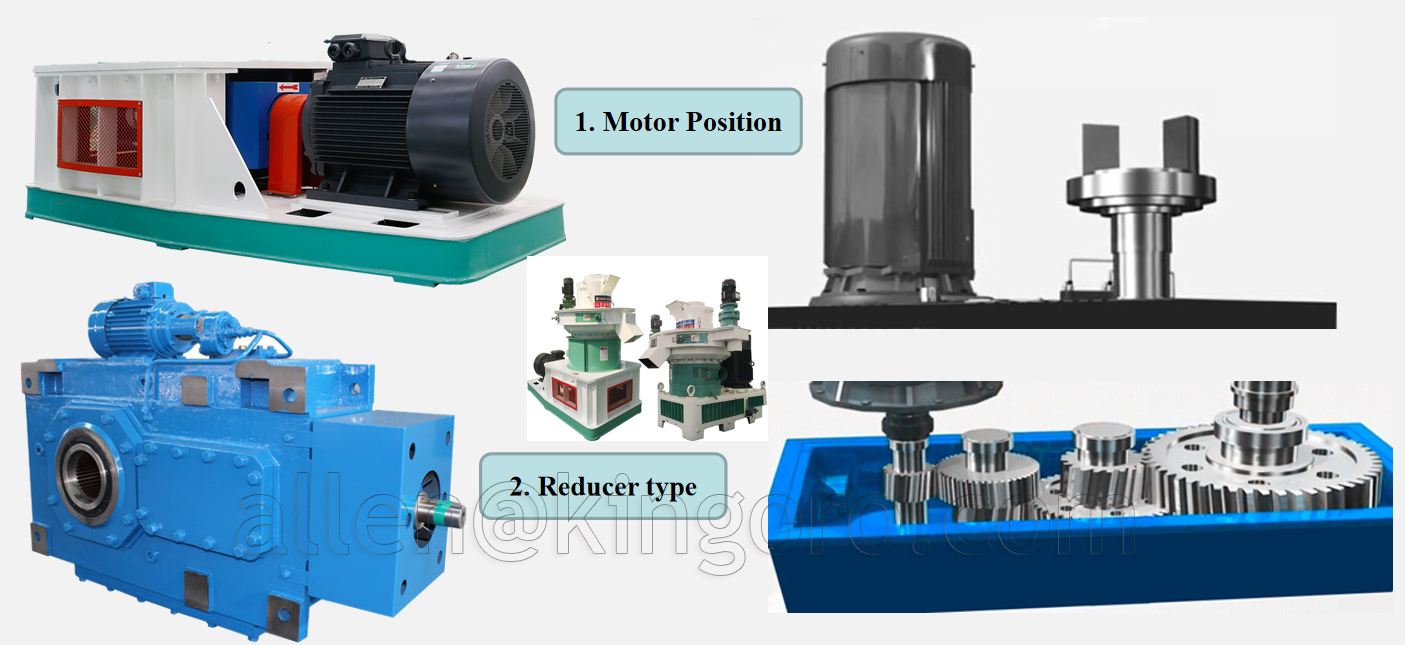

1. Big Gear Transmission

The gear of reducer is bigger(right picture), and the teeth joint surface becomes bigger, so its load bearing capacity is strenthened, which extends its service life longer 3-5 times

than usual reducer(left reducer)

2. Feeding Vertically

Raw material is feeding vertically and is directly in place, with stationary die and rotary pinch roller, the material is centrifugal and spread evenly around the die.

3.Doule Layer Ring Die

Each layer has 4-6 row of holes. The more holes, the much larger capacity.

The most important, Double layer extends ring die's service life. When one side is damaged or wornout, the other side is avaliable to be turned upside down to go on work.

4. Independent outlet device

The independent ejection device ensures the forming rate of pellet, the good design lowers the consumption and enhances the efficiency. It works 24 hours and lubricates automatically.

5. High Alloy Forged parts

The main load-carrying component used high alloy wear resistant materials. the wearing parts lifetime doubles compared with other similar products.

Stainless ring die and alloy steel ring die of kingoro wood pellet mill

Roller Skin of Kingoro Wood pellet mill

Requirements for biomass vertical Ring Die Biomass Wood Pellet Mill Machine

Size: All the raw materials must be crushed into sawdust (less than 7mm)before going into pellet mill

Moisture: Generally, 10-15% is best for quality biomass pellets.

All precesses of Biomass Pellet Production Line for making pellets

Pictures of biomass vertical ring die biomass wood Pellet Mill Machine

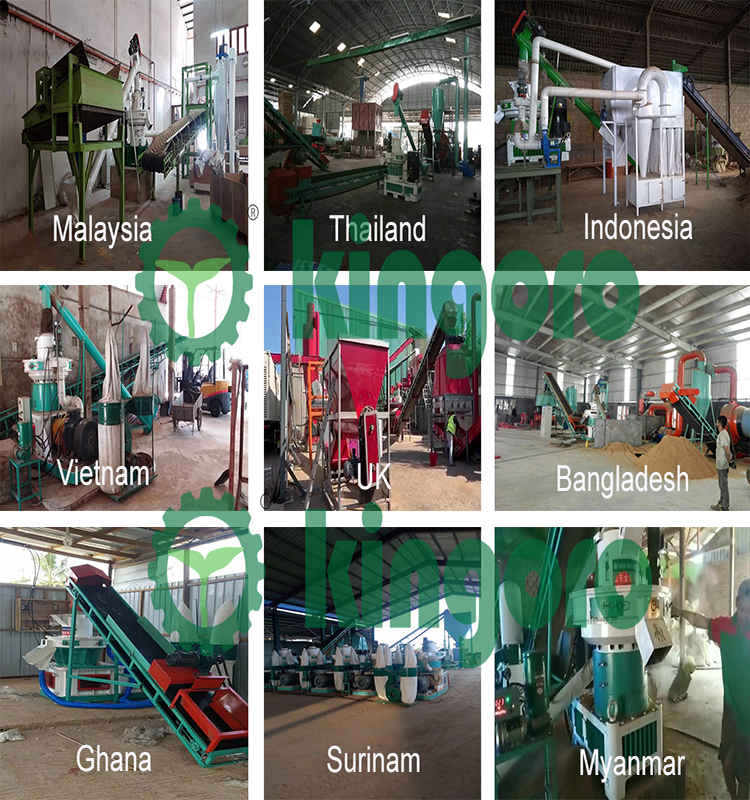

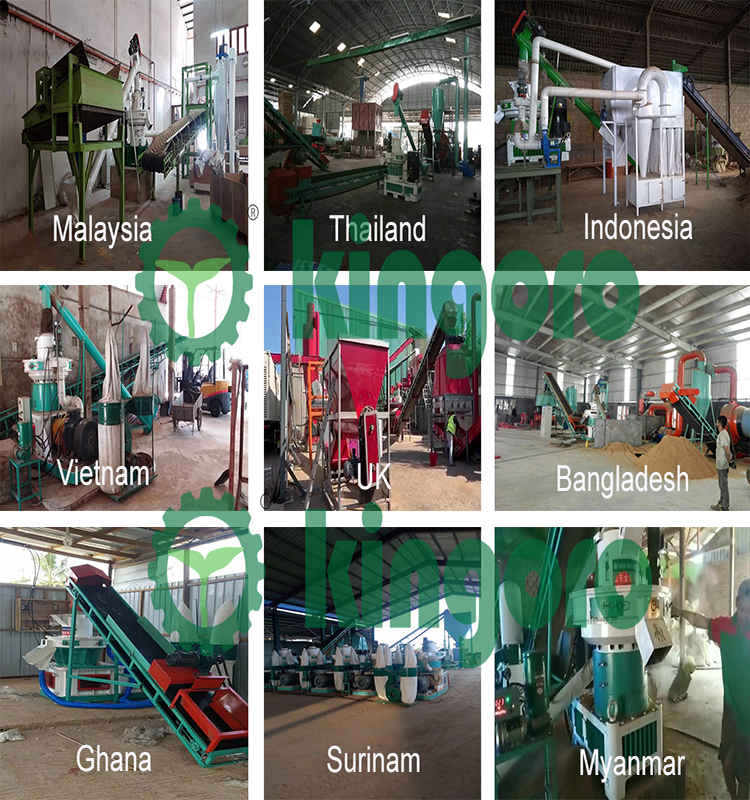

Client Cases of Kingoro Pellet production line

About our Factory

Shandong Kingoro Machinery Co.,Ltd, established in 1995, is specialized in manufacturing biomass fuel pellet making equipments, animal feed pellet making equipments and fertilizer pellet making equipments, including complete sets of a production line: crusher, mixer, dryer, shaper, siever, cooler, and packing machine.

According to specific requirements of our customers, we are enjoy to offer risk evaluation and turnkey solution plans.

We focus on inventation and innovation. 17 patents are our achievement in scientfic research.

Our products are certificated with ISO9001, CE, SGS Test Report.

Our Main Products

A. Biomass Pellet Mill

1.Vertical ring die pellet machine 2.Flat pellet machine

B. Feed Pellet Mill

C. Fertilizer Pellet Machine

D. Complete Pellet Production Line, including debarker, chipper, hammer mill, Screener, drum dryer, pellet machine, cooler, pacakging machine, etc

Certificates for pellet machine

When enquiry, if let us know the following information, you will get our quick response and better quotation.

1. What's the capacity you plan to produce?

2. What's the raw material?

3. What's the your raw material?

4. What's the moisture content of your raw materials?

5. What's your country voltage?

If Any Question, Please Leave Me Message Below.